Sandborn, the industry

Leader for your Emission

Control Needs.

Safe, Environmentally Friendly

Custom-Designed Unsinkable Floating Roofs

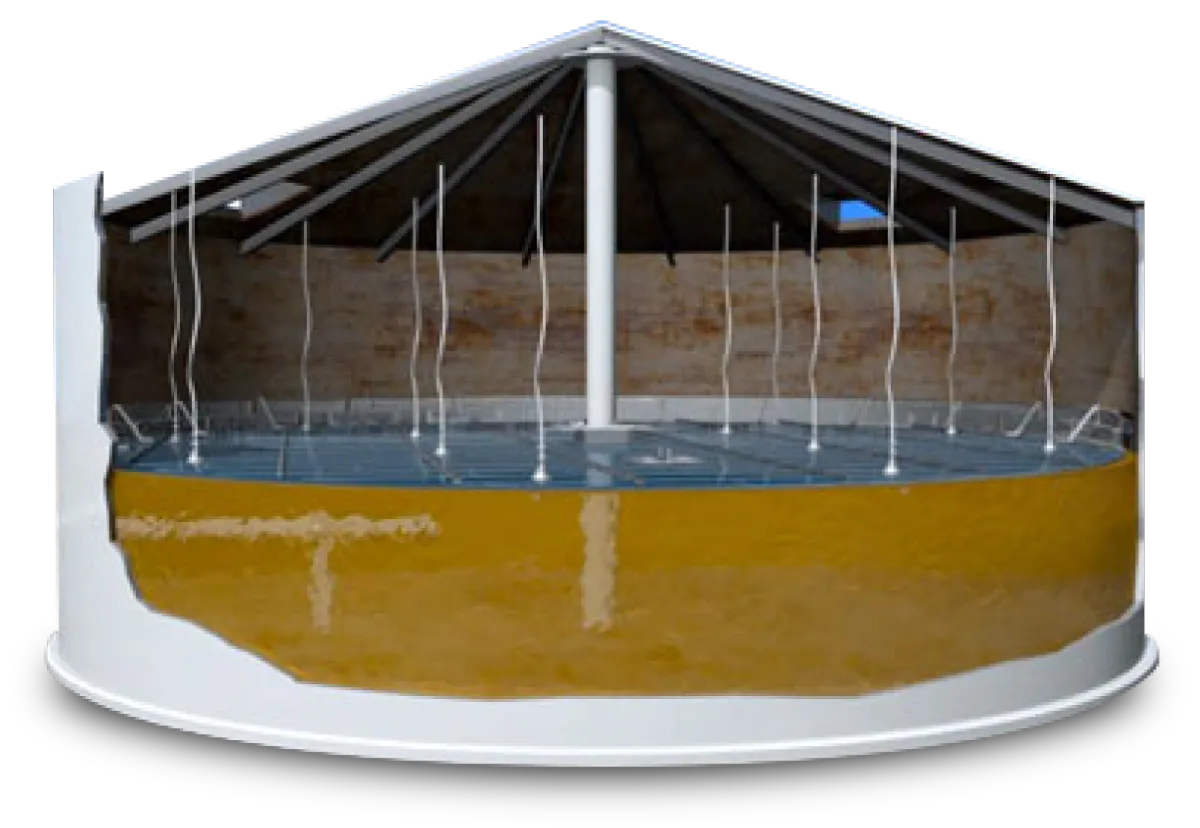

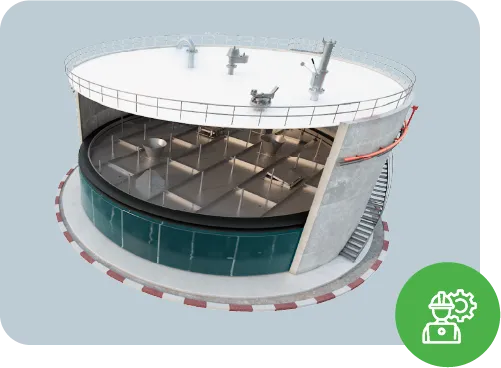

Internal Floating Roof System

Serving Oil & Gas Producers

around the world

Sandborn Roofs & Seals, the only call required to meet your floating roof and seal needs. With over four decades of expertise and hundreds of installations, we’ve earned the trust of companies worldwide.

Whether it’s a new tank or refurbishment of an existing tank, we have the knowledge, expertise and equipment designed to meet the highest emission control standards. With a variety of options available, Sandborn can deliver the solutions necessary to eliminate emissions and maximize tank operation. With our in-house engineering, design, fabrication and testing, it’s one call, period.

Why a full contact internal floating roof?

Simple, Emission Elimination.

Our floating roof provides the highest level of emission control available.

Sandborn Internal Floating Roofs are designed with product compatibility, seal systems, and safe effective support structures in mind.

Each component is designed to provide maximum efficiency.

With an industry exclusive 10 year anti-sinking warranty, the Sandborn Internal Floating Roof is the best solution for today’s tank operation.

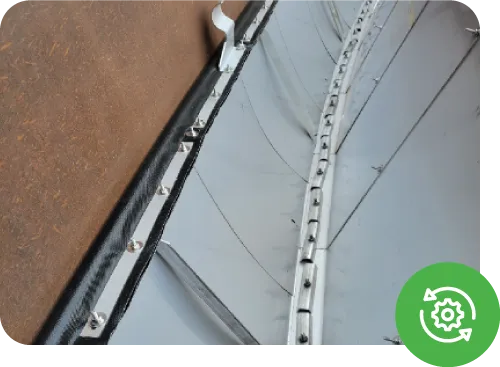

Floating roof seals can be exposed to extreme conditions.

Whether it be intense heat, cold or otherwise, a Sandborn seal is designed to exceed all standards and operate under the most demanding of conditions. Each Sandborn seal is custom manufactured & fully tested prior to shipment.

Our testing equipment enables us to replicate tank conditions

Ensuring a Sandborn seal assembly will provide the highest emission control and regulatory compliance under any and all operating conditions.

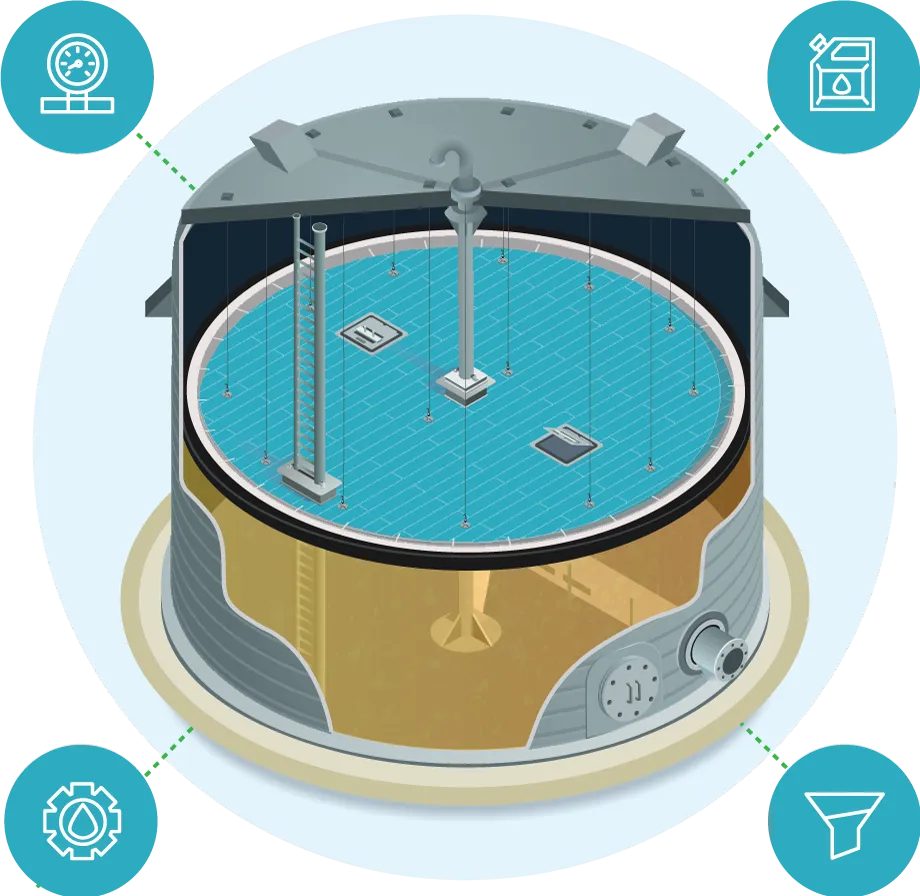

Our Internal Floating Roof System

Steel Floating

Roof Seals

Exposed to the harshest conditions. Whether it be extreme heat, extreme cold or otherwise, a Sandborn seal is designed to exceed all standards and operate under the most demanding conditions.

Key features that make Sandborn Seals

the preferred choice.

Custom Design

Sandborn seals are always custom-designed to meet the specific requirements of each storage tank and its contents. This ensures an optimal fit and performance.

Emission Control

Engineered and tested to provide the highest level of emission control. Designed to meet the most stringent regulatory standards.

Anti Rollover Technology

Sandborn Seals utilize patent pending anti-rollover technology unique to industry. Making a Sandborn Seal the most robust, adaptive and effective seal available. Performance like no other seal.

Ease of Installation

Sandborn seals are designed for easy installation and maintenance, minimizing downtime and operational disruptions.

Safety Features

Safety is a priority. A Sandborn seal is designed to operate in a safe and effective manner, with above industry standard components ensuring safe operation in any climate and under any circumstances.

Performance Optimization

Optimizing tank efficiency, performance and operating parameters are standard with a Sandborn designed seal.

Our Accessories

Deck Positioners:

We offer adjustable ‘patent pending’ deck positioners to ensure optimal seal performance regardless of tank condition and shell distortion.Skimmers:

A Sandborn skimmer system is designed to manage your fluid handling requirements. Gravity fed, pump assisted, jet fuel or product skimming. A Sandborn skimmer will deliver the results needed.Diffusers:

A critical component in managing product flow. A Sandborn designed diffuser exceeds API requirements to provide safe and effective tank filling.Circulation Vents:

Sandborn circulation vents are designed to provide multiple functions. Inspection portals for regulatory compliance and to provide a safe atmosphere within the tank.Overflow Vents:

Our overflows are designed to provide a back up to overfilling should the systems high level alarm or shut-off systems fail.Geodesic Dome Roof:

Our geodesic dome roofs are durable and weather resistant, offering the ease of construction and the ability to create large clear-span spaces.

Our Services

In-Service Inspections

Sandborn has the knowledge and ability to complete all types of ‘in service’ vessel entries and floating roof inspections. No need for costly draining and cleaning when Sandborn has the tools, equipment and knowledge necessary to complete the task with the tank remaining in service.

Sandborn has developed safe work procedures recognized as the industry standard for safe ‘in service’ tank entry. Be it an open top tank, cone roof tank or geodesic dome roof tank, we have the expertise to complete the entry and inspections safely!

In-Service Replacements

A damaged seal can lead to costly tank cleaning, downtime and lost revenue. Sandborn can help. We’ve developed a seal system and the necessary safe work procedures to enable seal replacement with the tank remaining in service. If there’s a problem with the seal, we’re ready to get the job done with a proven track record of safely removing and replacing damaged seal systems. We have completed numerous ‘in service’ seal replacements in tanks ranging from 30 ft. diameter to 270 ft. diameter. We have the expertise and ability to get the job done safely, efficiently and eliminating valuable down time.

Seal Repair

No seal repair is too big or too small for Sandborn to handle. Whether it’s a simple fix, partial replacement or a complete redesign and upgrade, we have the personnel and expertise to handle the job. Our design and drafting department excel in quick turnaround of seal design and our inspectors and installation crews have a wealth of experience in retrofitting and repairing ALL types of floating roof seal systems. Whether it’s a foam log seal, shoe seal, shoe with secondary or wiper seals, we can quickly assess the problem and arrive at a cost-effective solution.

Engineering Design

and Drafting

We take our work seriously at Sandborn Roofs. We have a professional design and drafting department capable of meeting the toughest redesign tasks. Not only do we design our own seal systems, we complete ‘in house’ testing of all seal assemblies prior to installation in the field. You can be assured that not only do our seal designs meet regulatory standards, but they’re also fully tested to each individual tank's condition, including shell anomalies and deformations. We pride ourselves in providing professional drawings detailing all seal components for easy identification. Our designs and drawings are reviewed and stamped by a professional engineer ensuring no detail is overlooked. Expect the highest standards from our design team!

Our Company History

Sandborn Roofs has been manufacturing and installing full-contact internal floating roof (IFR) systems since 1979, with hundreds of installations servicing oil and gas producers in North America and across the globe.

Trust Our Team of Experts

Sandborn Roofs' highly experienced staff and field crews offer our clients industry-leading expertise in floating roof systems.

The core of our success can be found in Sandborn's commitment to exceptional customer service and satisfaction.

Our mission is to supply producers highly-efficient, durable floating roof systems.

Serving Oil and Gas producers around the world

Sandborn Roofs has been manufacturing and installing full-contact internal floating roof (IFR) systems as well as seals, accessories and services since 1979, with hundreds of installations servicing oil and gas producers in North America and across the globe.

Locally Managed & Operated

Available 24/7

Ensuring regulatory compliance

Increasing safe tank operations

Protecting your investment

Offering Exceptional customer service

Our Team

Lee Gottschlich

President & CEO

Dave Vallee

General Manager

Derek Thiessen

Manager of Manufacturing

Jenna Gottschlich

Marketing & Sales Associate

Angela Wilson

Human Resources

Devin Bailey

NCSO

Copyright 2022 . All rights reserved

Office:

801 - 25th Avenue - Nisku, Alberta

Call

(780) 955-8761

Email:

info@sandbornroofs.com

Site:

www.sandbornroofs.com